Newsletter

Stay up to-date with the latest imaging, analysis and metrology news from Digital Surf.

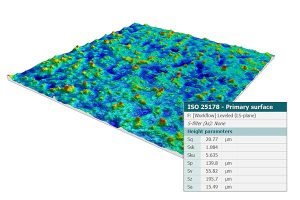

Analyze roughness and calculate surface texture parameters according to ISO 25178, ISO 4287, ISO 13565, ISO 21920 etc. and other national standards

Roughness and ISO parameters

Seperate roughness and waviness components of surfaces using the latest ISO 16610 advanced filtering techniques.

Access ISO parameters including:

Calculate & display ASME B46.1 2D and 3D parameters (USA), GB/T (China), DIN (Germany), JIS (Japan), NF (France), BSI (UK), UNE (Spain) and UNI (Italy) etc.

Perform functional analysis:

Prepare your measured data for analysis by removing outliers, local defects and noise.

Data correction

Normalize surfaces and remove artifacts prior to analysis. Tools include:

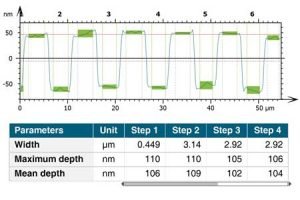

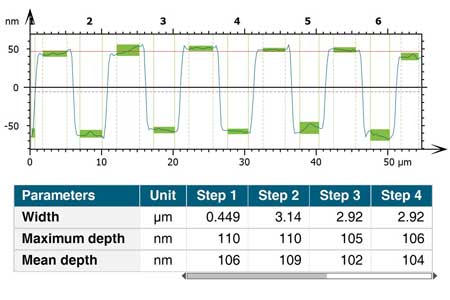

Analyze surface geometry: calculate distances, areas, step heights, volumes and much more.

Surface geometry

Perform fast and accurate analysis of surface geometry with tools for measuring:

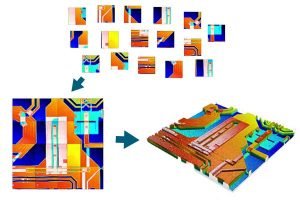

Increase profilometer range. Use stitching to expand range of all axes (including Z) and overcome instrument limitations.

Surface stitching

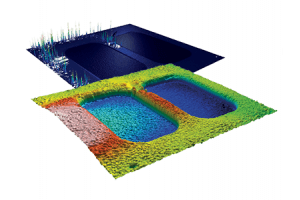

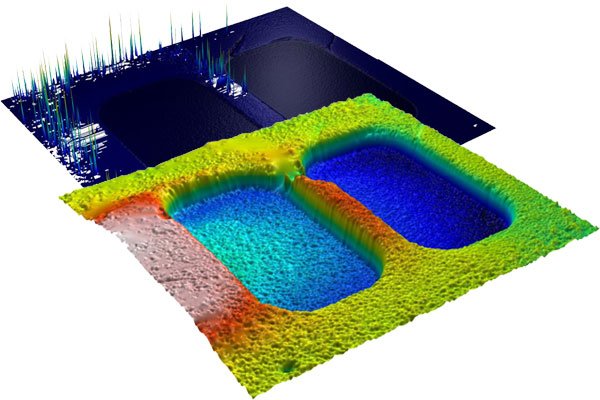

Extract and analyze regions of interest, then study them in the same way as complete measured surfaces.

Sub-surface analysis

Once a sub-surface or region of interest has been extracted it can be analyzed in exactly the same way as a full surface – parameters are calculated on the sub-surface only. This makes it possible, for example, to study the roughness, flatness and coplanarity of planes on MEMS and mechanical and electronic components.

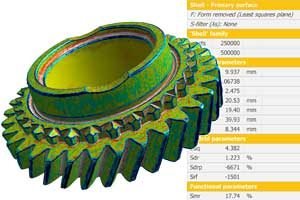

Shell (freeform surface) analysis

Shell visualization and analysis:

Perform metrological analysis on shells:

Compare measured Shells with CAD models:

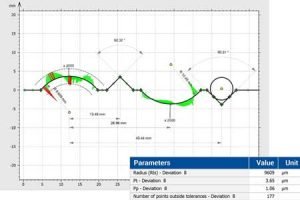

Advanced contour analysis

Carry out advanced surface texture analysis:

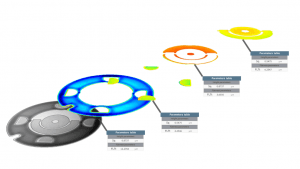

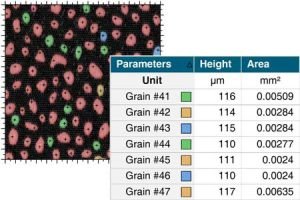

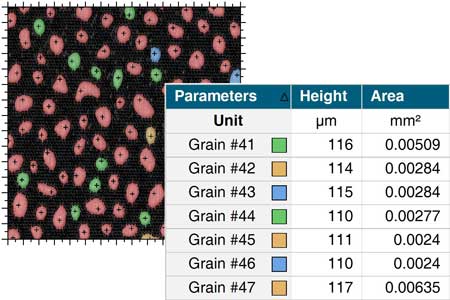

Particle analysis and more

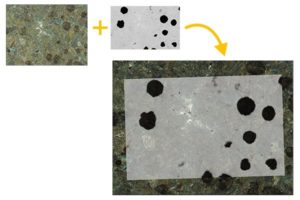

Particle analysis

Fourier & wavelets analysis

4D analysis

Thickness Analysis

Fiber Analysis

Perform correlative analysis and colocalize data from any profiler or microscope, all with the same software.

Correlative analysis

Left: colocalization of an SEM image and a light microscope image.

|

MountainsMap® Premium |

MountainsMap® Expert |

MountainsMap® Imaging Topography |

MountainsMap® Topography |

MountainsMap® Profile |

|---|---|---|---|---|---|

|

Instrument compatibility |

All profile and areal measuring instruments |

All profile and areal measuring instruments |

Areal optical profilers producing topography maps together with an intensity image and/or a color image

|

Areal optical or contact stylus profilometers producing topography maps

|

2D contact or optical profilometers |

Key features |

|||||

|

Profile roughness and waviness analysis |

|||||

|

Basic analysis of surface data |

|||||

|

Stitching of images and surfaces, outlier removal & multifocus reconstruction |

|||||

|

Support for file formats from optical profilers |

|||||

Optional modules |

|||||

|

Advanced profile analysis |

Option | Option | Option | ||

|

Automotive profile parameters |

Option | Option | Option | ||

|

Advanced topography analysis |

Option | Option | |||

|

Particle analysis |

Option | Option | Option | ||

|

Fiber Analysis of images & topography |

Option | Option | Option | ||

|

Contour Analysis |

Option | Option | Option | Option | |

|

Advanced Contour Analysis including CAD compare |

Option | Option | Option | Option | Option |

|

Thickness analysis |

Option | Option | Option | ||

|

4D Surface Change |

Option | Option | |||

|

Lens Analysis |

Option | Option | Option | Option | |

|

Fourier & Wavelets Analysis |

Option | Option | Option | ||

|

Shell Extension (freeform surfaces) |

Option | Option | Option | ||

|

Shell Topography for metrological analysis |

Option | Option | Option | Option | |

|

Shell CAD compare |

Option | Option | Option | Option | |

|

Lead Analysis (Twist) |

Option | Option | Option | Option | |

|

Scale-Sensitive Fractal Analysis |

Option | Option | Option | Option | |

|

Colocalization for Correlative Analysis |

Option | Option | Option | ||

The following range of optional modules for advanced and specialized applications is available with the MountainsMap® range.